Blog

What is Damascus Steel: Discover Its Secrets, History, and 7 Fascinating Facts

Damascus steel is a legendary material famous for its beauty, strength, and rich history. With its distinct wavy patterns, this unique metal has captivated the imagination of many for centuries. Today, it’s used in knives, swords, jewellery, and even modern technology. But what makes Damascus steel so unique? In this article, we’ll explore the origins, making, uses, and distinctive features of Damascus steel and delve into why it’s still one of the most sought-after materials in various industries. You’ll also discover seven fascinating facts that make it even more intriguing.

What is Damascus Steel?

Damascus steel refers to a form of steel used in the production of blades, historically dating back to around 300-500 AD. The term “Damascus” originates from the city of Damascus, which was historically a centre for the production of weapons. The steel itself is renowned for its distinctive patterned surface, which appears as swirling, water-like designs. But beyond its visual appeal, Damascus steel is known for its excellent combination of hardness, strength, and flexibility—ideal characteristics for making sharp, durable blades.

The Origins of Damascus Steel

The true origins of Damascus steel are somewhat shrouded in mystery, but it is believed to have been developed in ancient India and Sri Lanka before spreading to the Middle East. The steel’s history is entwined with the rise of the Islamic empires, where it gained prominence in sword production. The famous Wootz steel, a precursor to Damascus steel, was produced in India and became the foundation for what would be known as “Damascus steel.”

The Unique Characteristics of Damascus Steel

What sets Damascus Steel apart is its distinctive pattern, which is not just ornamental but a result of specific manufacturing techniques. The pattern is formed through the folding and welding of multiple layers of steel, a process that creates wavy, flowing designs on the surface. This layering also contributes to the blade’s unique properties—combining hardness and flexibility.

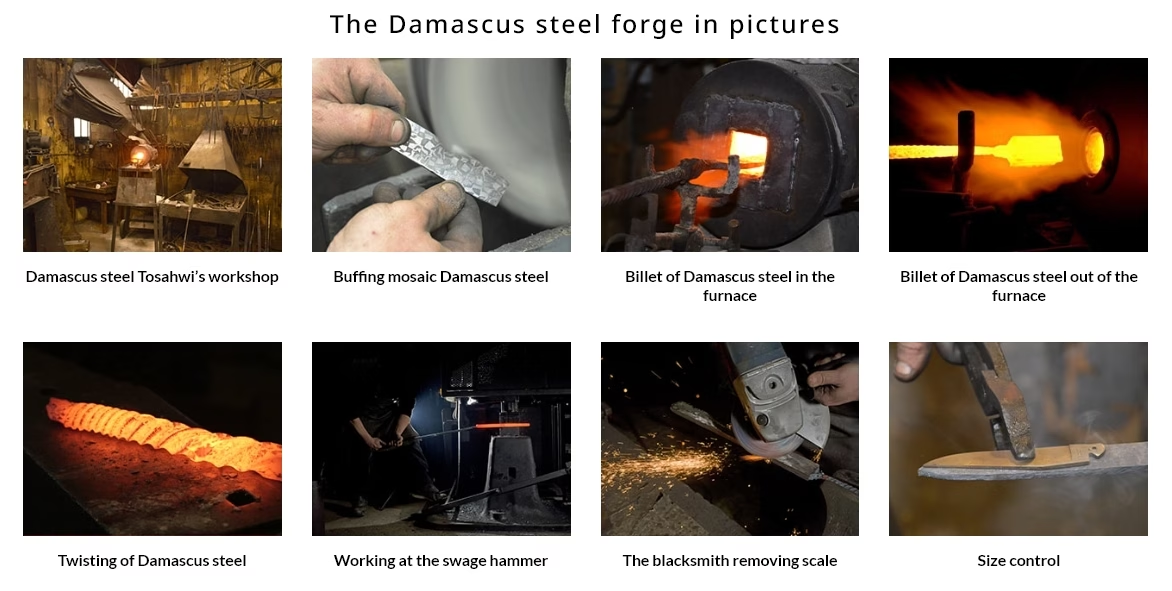

How Damascus Steel is Made

Damascus steel is created using two main methods: traditional Wootz steel production and modern pattern welding. Each method has contributed to the unique characteristics that make Damascus steel highly sought after.

The Traditional Method: Wootz Steel Production

The ancient process for creating Damascus steel involved the use of Wootz steel, an ingot-based material that originated in India. Wootz steel was produced by melting iron in a crucible with carbon-rich materials, which resulted in a high-carbon steel with distinct crystalline structures. The ingots were then forged and hammered to produce blades that exhibited the characteristic patterns we now associate with Damascus steel.

The Modern Approach: Pattern Welding

In modern times, Damascus steel is produced using a method known as pattern welding. This method involves layering different types of steel (typically high-carbon and low-carbon) and welding them together under extreme heat. The metal is then folded and hammered repeatedly, resulting in the iconic swirls and patterns seen on the surface of the blade. The combination of layers also gives the material superior strength and edge retention.

Why Damascus Steel is So Sought After

Damascus steel has captured people’s imaginations for centuries. But beyond its stunning appearance, there are practical reasons why it remains a favourite in blade production and other industries.

Its Exceptional Strength and Durability

One of the key factors that makes Damascus steel so desirable is its durability. The steel’s layered construction gives it both toughness and flexibility, allowing it to withstand extreme forces without breaking or chipping. The strength of Damascus steel ensures that blades made from this material maintain sharpness and retain their edge for a longer period compared to regular steel.

The Aesthetic Appeal: The Unique Pattern of Damascus Steel

Of course, the signature feature of Damascus steel is its beautiful, flowing patterns. These patterns are not merely decorative—they signify the quality of the steel and the complex forging process that has gone into making the material. Each piece of Damascus steel is unique, making it a prized material for custom knives and swords.

The Uses of Damascus Steel Throughout History

Damascus steel has been used for centuries, primarily in weaponry, but its applications have expanded to include a wide variety of products.

From Ancient Swords to Modern Knives

In ancient times, Damascus steel was used to make swords and daggers, which were known for their sharpness and ability to hold an edge. The famous Damascus steel blades were highly prized for their ability to cut through armour while remaining tough enough to survive the battle. Today, Damascus steel is used in the production of knives, especially high-end chef knives and custom-made knives.

Damascus Steel in Modern Technology

While Damascus steel is most famous for its use in blades, its unique properties also make it valuable in other industries. Modern engineers have begun to explore the material for use in advanced machinery and technology, where its toughness and corrosion resistance are highly valued.

Key Advantages of Damascus Steel Over Other Metals

When compared to other metals and alloys, Damascus Steel stands out for its exceptional performance in several areas.

Corrosion Resistance and Toughness

Damascus steel is highly resistant to corrosion, making it ideal for items like knives that are exposed to water and other harsh elements. The steel’s layered structure also enhances its toughness, preventing breakage and damage during heavy use.

Sharpening and Edge Retention

Due to the combination of high-carbon and low-carbon steels, Damascus steel can hold an edge longer than other metals. It sharpens easily and stays sharp for longer, making it a preferred choice for blades that need to perform under pressure.

How to Care for Damascus Steel

Taking care of Damascus steel requires some specific attention to maintain its appearance and functionality.

Cleaning and Maintenance Tips

To clean Damascus steel, avoid harsh chemicals or abrasive materials. Instead, use a soft cloth to wipe down the blade and mild soap if needed. It’s also essential to dry the steel thoroughly after use to prevent rust.

The Best Ways to Store Damascus Steel

To maintain the quality of Damascus steel, store it in a dry, cool place. Use protective oil to coat the blade and prevent corrosion. When storing knives or blades, it’s best to keep them in protective sheaths or cases to avoid accidental damage to the edge.

Common Misconceptions About Damascus Steel

With all its fame and intrigue, there are a few common misconceptions about Damascus Steel.

Is Damascus Steel Fake or Real?

There are many fake versions of Damascus steel available on the market. Genuine Damascus steel is created through specific techniques and processes, while imitations are often made from cheap materials with similar patterns that lack the inherent qualities of the real thing.

What’s the Difference Between Damascus Steel and Stainless Steel?

While both Damascus steel and stainless steel are durable, the main difference lies in the carbon content. Damascus steel is typically higher in carbon, making it more challenging and better at holding an edge. Stainless steel, on the other hand, is more resistant to rust and corrosion but doesn’t offer the same sharpness or edge retention as Damascus steel.

Popular Damascus Steel Products

Today, Damascus steel is used in a variety of products, from practical tools to luxury items.

Damascus Steel Knives and Swords

Damascus steel is most commonly used in knives and swords. High-end Damascus knives are popular among chefs, collectors, and outdoor enthusiasts for their durability and sharpness. Some sword collectors also seek out authentic Damascus blades for their historical significance and craftsmanship.

Damascus Steel in Jewelry and Watches

In addition to knives, Damascus steel is also used to make unique jewellery pieces, such as rings, bracelets, and pendants. Some high-end watch manufacturers also incorporate Damascus steel into watch bands or cases for its striking appearance and durability.

The Future of Damascus Steel

As technology advances, Damascus Steel continues to evolve. New methods of production are making it more accessible and improving its properties.

Innovations and Technological Advances

Innovations in metallurgy and forging techniques are allowing manufacturers to produce Damascus steel more efficiently while retaining its desirable characteristics. Some modern versions of Damascus steel are being created with alloys that enhance performance and durability.

Sustainability and Ethical Sourcing in Damascus Steel Manufacturing

As demand for Damascus steel increases, there’s a growing emphasis on sustainable and ethical sourcing practices. Manufacturers are focusing on ensuring that the raw materials used in making Damascus steel are responsibly sourced and that the production process minimizes environmental impact.

Frequently Asked Questions (FAQs)

1. How do I know if a blade is made from real Damascus steel?

Real Damascus steel will have distinctive wavy or swirling patterns on its surface. Genuine Damascus steel is created by folding and welding layers of steel together, resulting in a unique appearance. Fake Damascus often uses surface etching to mimic the pattern without offering the same strength.

2. Is Damascus steel more expensive than regular steel?

Yes, Damascus steel is often more expensive than regular steel because it requires more labour-intensive production methods—the materials and expertise involved in making it contribute to the cost.

3. Can Damascus steel be used for everyday knives?

Absolutely. Damascus steel knives are not only beautiful but also functional. They’re highly durable, maintain sharp edges, and can handle regular kitchen or outdoor use.

4. Is Damascus steel rust-resistant?

Damascus steel is resistant to corrosion, but it still requires proper care to avoid rusting. Regular cleaning, drying, and coating the blade with oil can help maintain its appearance and functionality.

5. How long will a Damascus steel blade last?

With proper care, a Damascus steel blade can last a lifetime. Its durability and edge retention make it an investment for anyone who uses knives regularly.

6. Can I make my own Damascus steel at home?

While it’s technically possible to make Damascus steel at home, the process is complex and requires specialized equipment. Many hobbyists and blacksmiths enjoy forging their blades, but it requires a lot of skill and practice.

Conclusion

Damascus steel is a material of both beauty and function, blending centuries of craftsmanship with modern innovation. Its rich history, coupled with its unparalleled strength, sharpness, and visual appeal, makes it a material that stands the test of time. Whether used for blades, jewellery, or technology, Damascus Steel continues to captivate and inspire.