Centuries of Steel, Forged into Perfection

Explore the Legacy

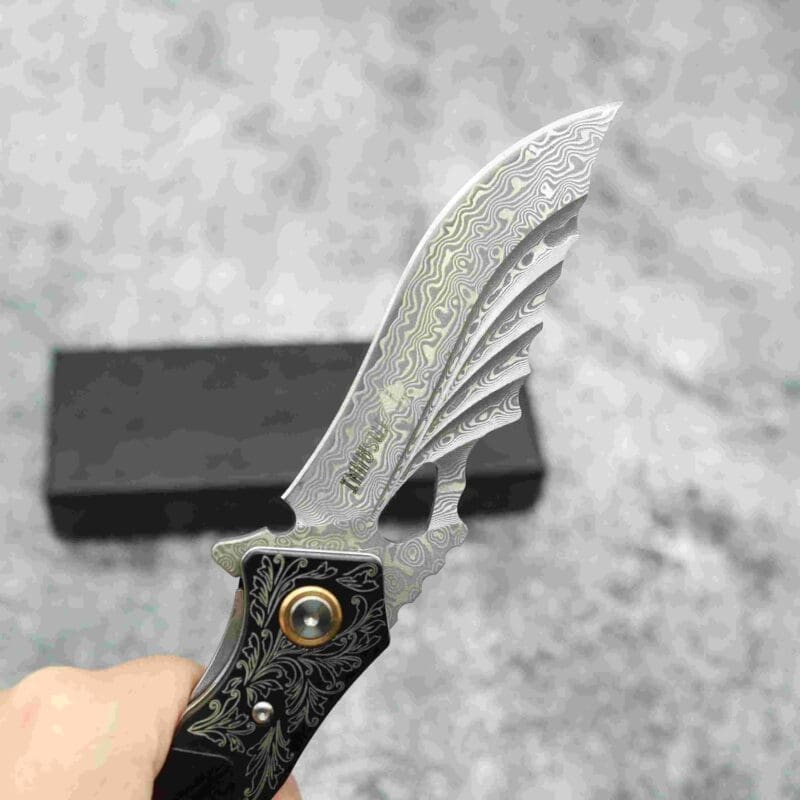

The Art of Damascus Steel Knife

Billet Preparation & Forge Welding

The process begins by stacking alternating layers of high-carbon and low-carbon steel to form the billet. This billet is then heated in a controlled furnace until it reaches the optimal forging temperature. While still red-hot, it is hammered to fuse the layers into a single, uniform block, ensuring exceptional strength and integrity.

Folding & Layering

To enhance the steel’s durability and create the signature Damascus patterns, the billet is drawn out, cut, and folded over itself multiple times. Each repetition increases the number of layers, refining the steel’s structure and enhancing its distinctive wavy patterns.

Shaping & Heat Treatment

Once the desired number of layers is achieved, the billet is shaped into the blade’s form through precision hammering and grinding. The heel and edge are refined to exact specifications, followed by a heat treatment process—oil quenching strengthens the steel, ensuring superior edge retention and resilience.

Etching & Finishing

The final step involves honing and buffing the blade to perfection. To reveal the iconic Damascus pattern, the blade is immersed in an acid bath, which reacts with the layered steel to create striking contrasts. A neutralizing bath preserves the finish, resulting in a blade that is not only a work of art but a high-performance cutting tool.